Our Facility

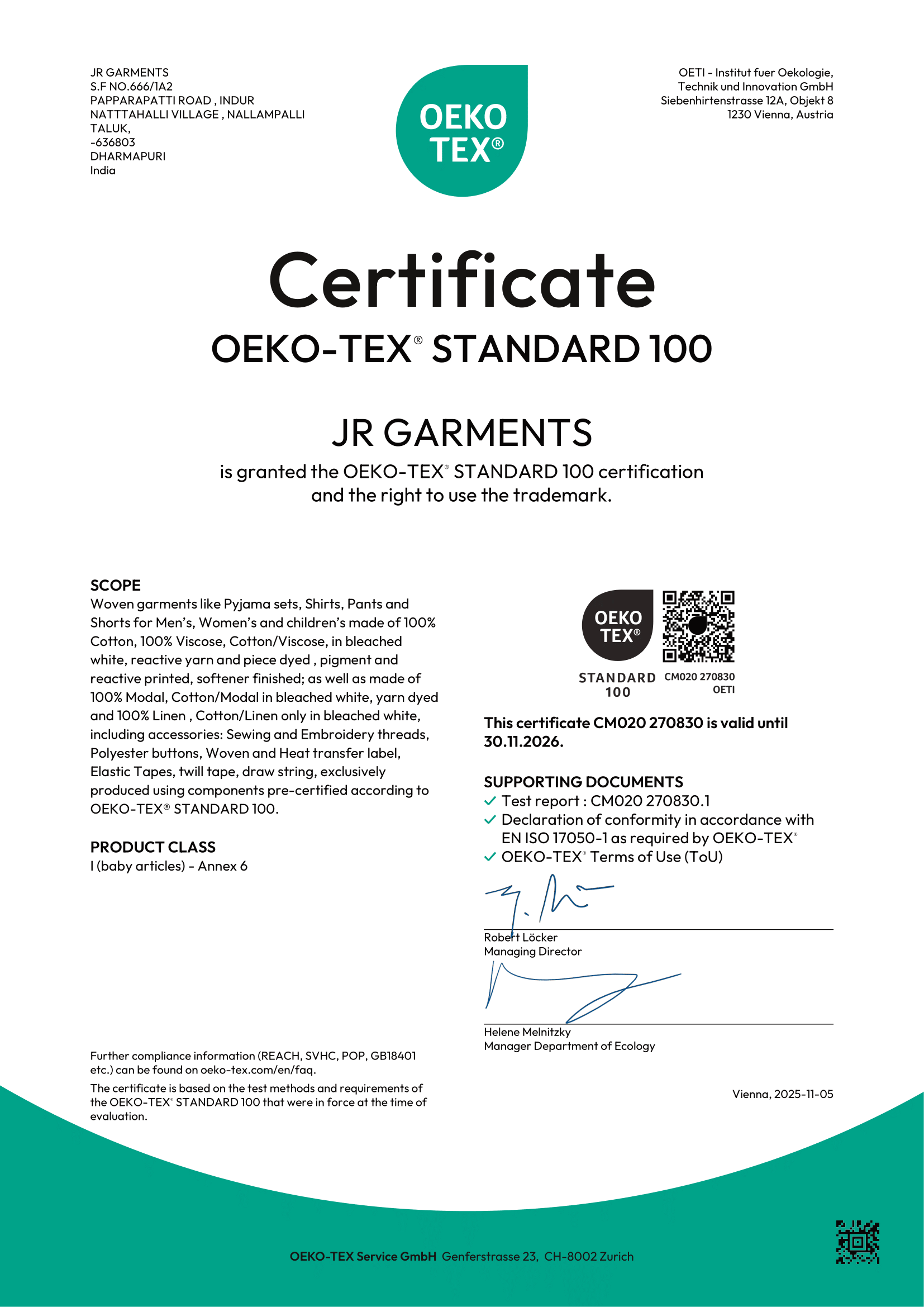

Certifications & Compliance

Worker-friendly, audit-ready operations with ethical practices, structured health & safety, and inline QA. Documentation available on request.

Capabilities & KPIs

Equipped for woven programs end-to-end: single-needle, double-needle, overlock & flatlock stations; snap, bartack and elastic (Kansai) attachments; accurate cutting and collar roll fusing; steam/vacuum finishing with compliant pack, label and barcode execution. Lines are balanced for throughput with inline AQL at control points and 100% final checking before pack.

Workflow

A clear path from fabric to export-ready cartons.

-

Fabric Sourcing

Fabric Sourcing

We triangulate mills across Salem, Erode, Tirupur, Bangalore & Mumbai to balance handfeel, timelines and landed cost.

-

Cutting

Cutting

Fabric relax, shrinkage controls and precise markers deliver consistent panels; safety gates before bundling.

-

Sewing

Sewing

Balanced stations with line feeding and inline AQL. Operator training emphasizes SPI, seam strength and repeatability.

-

Buttoning / Bartack

Buttoning / Bartack

Stress-point reinforcements with bartack, button, snap & elastic attachments as per buyer SOPs.

-

Trimming & QA

Trimming & QA

Defect segregation with a documented rework loop. Optional needle/metal policies available per brand.

-

Press & Pack

Press & Pack

Steam/vacuum finishing. Pack, label and barcode execution aligned to ship mode and DC rules.

-

Carton Storage

Carton Storage

Moisture-care storage, palletization and export-ready documentation for on-time dispatch.

-

Fabric Sourcing

Right mills, right lead time.

We triangulate mills across Salem, Erode, Tirupur, Bangalore & Mumbai to balance handfeel, timelines and landed cost.

-

Cutting

Relax → mark → cut.

Fabric relax, shrinkage controls and precise markers deliver consistent panels; safety gates before bundling.

-

Sewing

Balanced lines + inline AQL.

Balanced stations with line feeding and inline AQL. Operator training emphasizes SPI, seam strength and repeatability.

-

Buttoning / Bartack

Stress-point reinforcements.

Stress-point reinforcements with bartack, button, snap & elastic attachments as per buyer SOPs.

-

Trimming & QA

Defect segregation & rework loop.

Defect segregation with a documented rework loop. Optional needle/metal policies available per brand.

-

Press & Pack

Finish, label, barcode per SOP.

Steam/vacuum finishing. Pack, label and barcode execution aligned to ship mode and DC rules.

-

Carton Storage

Palletized, export ready.

Moisture-care storage, palletization and export-ready documentation for on-time dispatch.